Welcome to Modina Agro Product

-

-

Mon - Sat 8:00 - 6:30, Sunday - CLOSED

Welcome to Modina Agro Product

Mon - Sat 8:00 - 6:30, Sunday - CLOSED

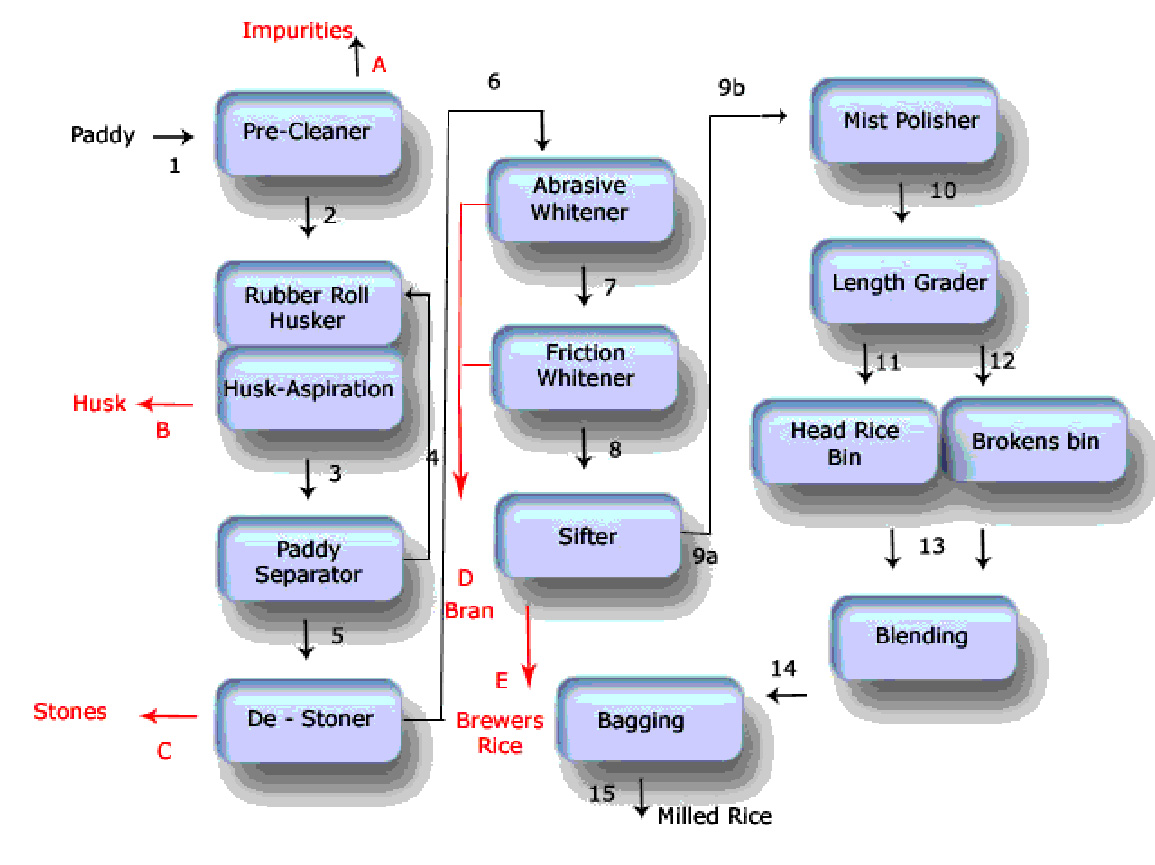

The Rice milling is the process that helps in removal of hulls and bran’s from paddy grains to produce polished rice. Rice is rich in genetic diversity with thousands of varieties grown throughout the world. Rice has been one of man's most important foods.

Today, this unique grain helps sustain two-thirds of the world's population. It is life for thousands of millions of people. It is deeply embedded in the cultural heritage of their societies. About four-fifths of the world's rice are produced by small-scale farmers and are consumed locally. Milling is the process wherein the rice grain is transformed into a form suitable for human consumption, therefore, has to be done with utmost care to prevent breakage of the kernel and improve the recovery. The present paper lucidly explains rice milling process and its importance.

Paddy or rice grain consists of husk and brown rice. Brown rice, in turn, contains bran which comprises the outer layer and the edible portion. Rice milling is removal or separation of husk (dehusking) and bran to obtain the edible portion for consumption. The process has to be accomplished with care to prevent excessive breakage of the kernel and improve recovery of paddy or rice. The extent of recovery during milling depends on many factors like variety of paddy, degree of milling required, the quality of equipments used, the operators, etc. Milling is the process wherein the rice grain is transformed into a form suitable for human consumption, therefore, has to be done with utmost care to prevent breakage of the kernel and improve the recovery. Brown rice is milled further to create a more visually appealing white rice. After harvesting and drying, the paddy is subjected to the primary milling operation which includes de-husking as well as the removal of bran layers (polishing) before it is consumed. In this process the rice which is obtained after milling is called raw rice. An other process through which rice is obtained after milling is called "Parboiling Rice." Nearly 60% of the total rice produced in India is subjected to parboiling. Rice milling losses may be qualitative or quantitative in nature. Quantitative or physical losses are manifested by low milling recovery while low head rice recovery or high percentage of broken kernel reflects the qualitative loss in rice grains.

Traditional Method: Before the advent of mechanical milling, hand-pounding traditional method of rice milling was in practice. In fact, hand-pounding rice has got more nutritive value as compared to machine milling rice. In hand-pounding, a variety of implements is used such as :Mortor and Pestle, Hand Stone (Chakki)etc 2.2) Mechanical Method:With the introduction of mechanized mills, hand-pounding method has steadily decreased because it could not compete with machine mills. The conventional mills in use can be categorized into three main types :

Huller mills

Sheller-Huller mills

Sheller-Cone Polisher mills

Although harvested paddy grain may have gone through a cleaner before drying, wet paddy is difficult to clean thoroughly. Cleaning paddy prior to husking and whitening is crucial in attaining high milling recoveries.

A simple pre-cleaner used in rice mills usually contain an oscillating double screen bed with an aspirator. The first screen is a scalper that lets through the grain but retains straw. The second screen retains the grains but lets through broken grains and small stones or weed seeds. The air aspirator sucks out dust and the light empty grains. Air dampers are provided and have to be adjusted to prevent the good grain from being sucked out.

Husking or de-hulling is a process for removing the rice hull from the rough rice.

Three different husking technologies are commonly used: Steel husker, underrunner disk husker and rubber roller husker. In order to separate the remaining unhusked paddy grains from from the brown rice fraction and feed them back into the husker a paddy separator is used.

The performance of a husker can be expressed by the husking efficiency, which is the % of husked rice in total grain flow. In a properly adjusted rubber roll husker, husking efficiencies can be as high as 95%, however efficiencies are often lower. Besides machine adjustments, uniformity of grain thickness will affect the husking efficiency. If a mixture of varieties is fed into the husker, or paddy grain that did not mature uniformly in the field, husking efficiencies will be lower.

The steel husker is in fact more than a husker since it also does the polishing. It is an adaptation of the "Engleberg" coffee huller, modified for milling rice. In earlier days this type of rice mill was very popular in most rice-growing countries. The "iron hullers", or "single pass mills" which all refer to the same mill are notorious for breaking the paddy grain. The fine brokens are mixed with the bran and the ground rice hull. The steel husker removes the husks and whitens the rice in one pass. Paddy rice is fed into the machine and passes between a revolving steel shaft and a cylindrical shaped mesh screen. These machines are normally powered by a 5 to 20 hp engine and are very simple to operate. They are relatively cheap.

Because of the high breakage, the total milled rice recovery is 53-55%, and head rice recovery is in the order of 30% of the milled rice.

Very compact

Easy to operate

Low cost and easy to maintain

Can mill small amount of paddy for individual farmers

Low cost of milling (handling and conveying equipment is minimal)

Low milling efficiency

Produces high amount of cracked and broken rice

LBy-products - husk, bran and very small broken are often mixed

The rubber-roller huller is the most efficient hulling machine. As the name suggests two rubber rollers of the same diameter are operated at different speeds to remove the husk from the paddy. One roller has a fixed position and the other is adjustable to meet the desired clearance. The adjustable roller rotates slightly slower than the fixed roller. Rubber-roll hullers have an aspirator in the base of the machine to separate the hulls from the brown rice. The roll diameter varies from 150 to 250 mm and the roller width from 60 to 250 mm. The correct clearance is dependent on the varietal characteristics and the width and length of paddy. This method of hulling can achieve hulling efficiencies of 85% to 90% with minimum broken or cracked grain. This type of machine is now widely used in developed countries.

Huller mills

Sheller-Huller mills

Sheller-Cone Polisher mills